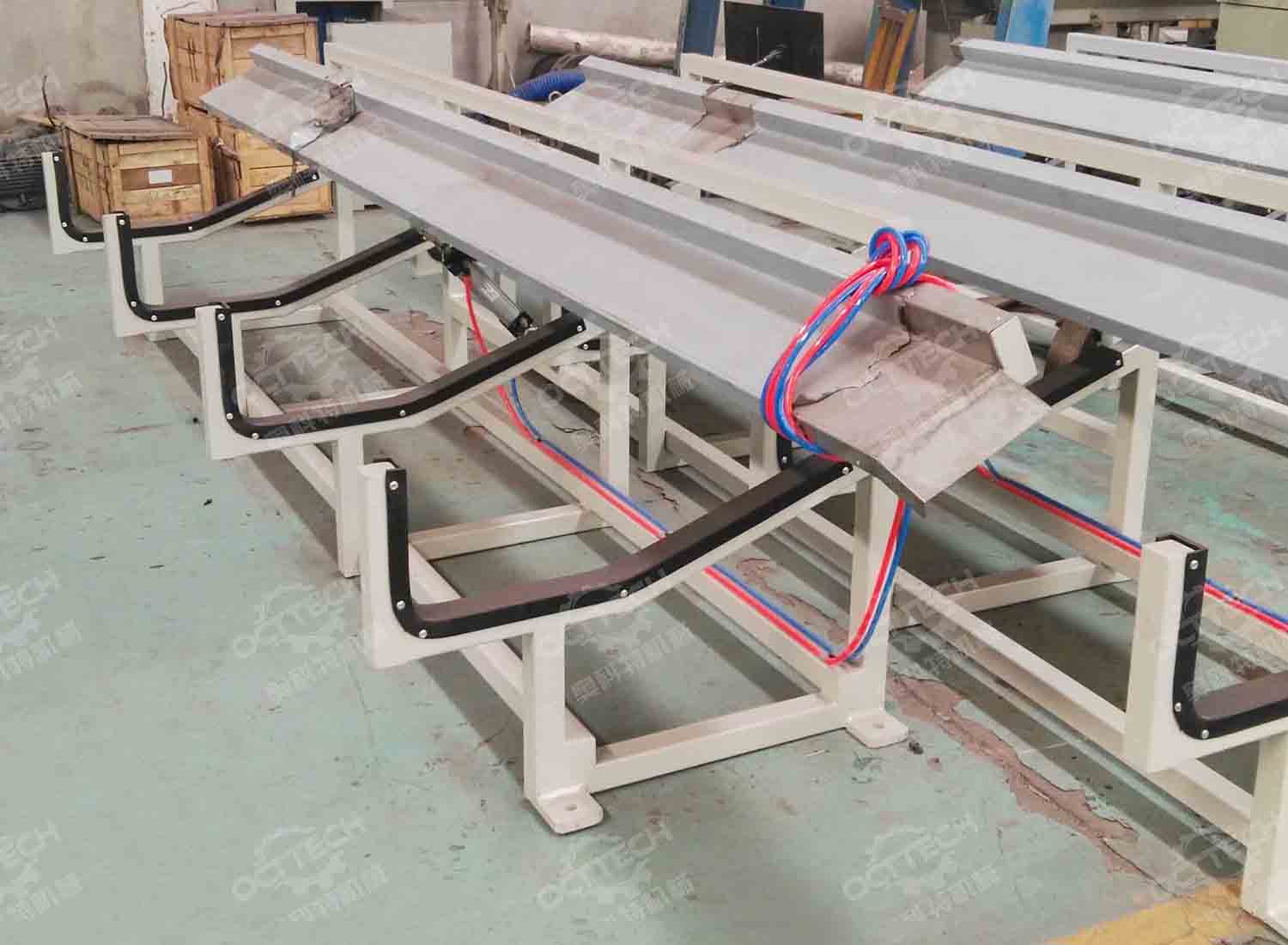

PVC Double pipe extrusion line

PVC double pipe and four pipe line is mainly used to make PVC water supply pipe ,drainage pipe,Conduit Pipe and other area.The production line equipped with high efficient& energy saving twin conical screws extruder,produces PVC pipe two or four outlet at once by specially designed die mould.

Technical Parameters

| Model | Pipe diameter(mm) | Extruder | Die head | Capacity(kg/h) | Main power(kw) | Total power(kw) | Line length(m) |

|---|---|---|---|---|---|---|---|

| UPVC40 | 16-40 | SJZ51/105 | Double outlet | 80-120 | 18.5 | 50 | 22 |

| UPVC63 | 16-63 | SJZ65/132 | Double outlet | 120-250 | 37 | 100 | 25 |

| UPVC32 | 16-32 | SJZ65/132 | Four outlet | 120-250 | 37 | 100 | 22 |

PVC double pipe extrusion line Working Flow

Screw loader→Conical twin screw extruder→Mould→Vacuum calibration tank→Haul off and Cutter machine→Stacker→Electric control cabinet

PVC double pipe extrusion line Detail

Vacuum exhaust system

High torque reducer,use water cooling control temperature

Die mouth , mandril :40Cr

Calibration copper sleeve :Tin bronze

Equipped with water temperature and water level controlled by Floating ball switch.

Print word:Depth≤0.3mm,print line min width:0.05mm,word height:0.5-100mm

Clamp by gas cylinder, easy for regulating clamp force.

Cutter Type:fly cutter

Haul off and cutter is controlled separately

Japan “Omron” temperature controller

Taiwan “TECO” Invertor

France “Schneider” contactor

service advantage

professional installation

Octtech has a professional equipment installation team with professional training and years of service experience. With excellent skills and tools, Octtech can provide fast and reliable lithium battery mixer installation services.

Quick response

The normal operation of the equipment is very important to your work efficiency, so we arrange local professional service technicians all over the country, arrive at the scene within 2 hours, and provide the optimal maintenance solution.

user training

Octtech will rely on its own resource advantages to provide high-quality training services. Let you firmly grasp how to operate the equipment proficiently; understand some basic equipment daily maintenance knowledge.

excellent product

Related Hot Products

PEX-A pipe machine

This machine uses a plunger extruder to produce PEX plastic pipes. The production process of PEX pl…

The PE wax flakes extrusion m…

The PE wax extruder machine for flake is for extruding PE wax from PE waste like waste pe wires,pe …

PET Strap plastic extrusion m…

PET PP strap is used as a new environmentally friendly packaging materials in place of steel strap …

WhatsApp

WhatsApp

Wechat

Wechat