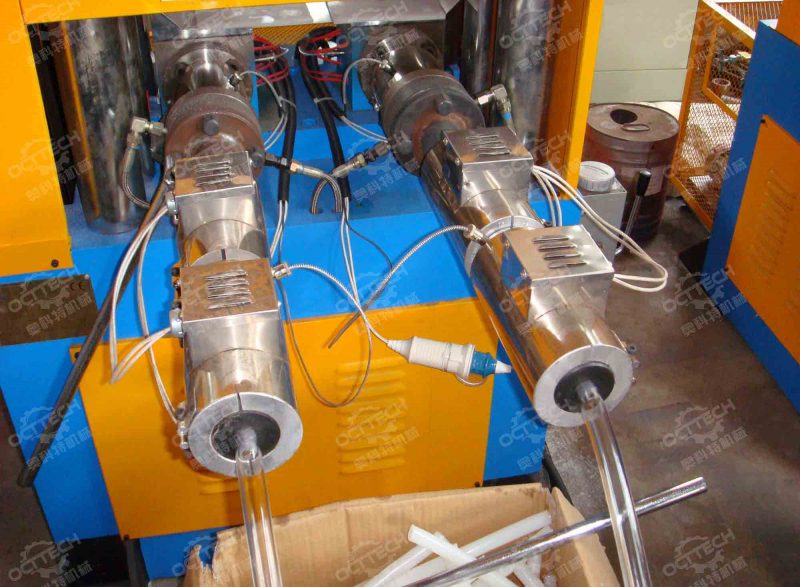

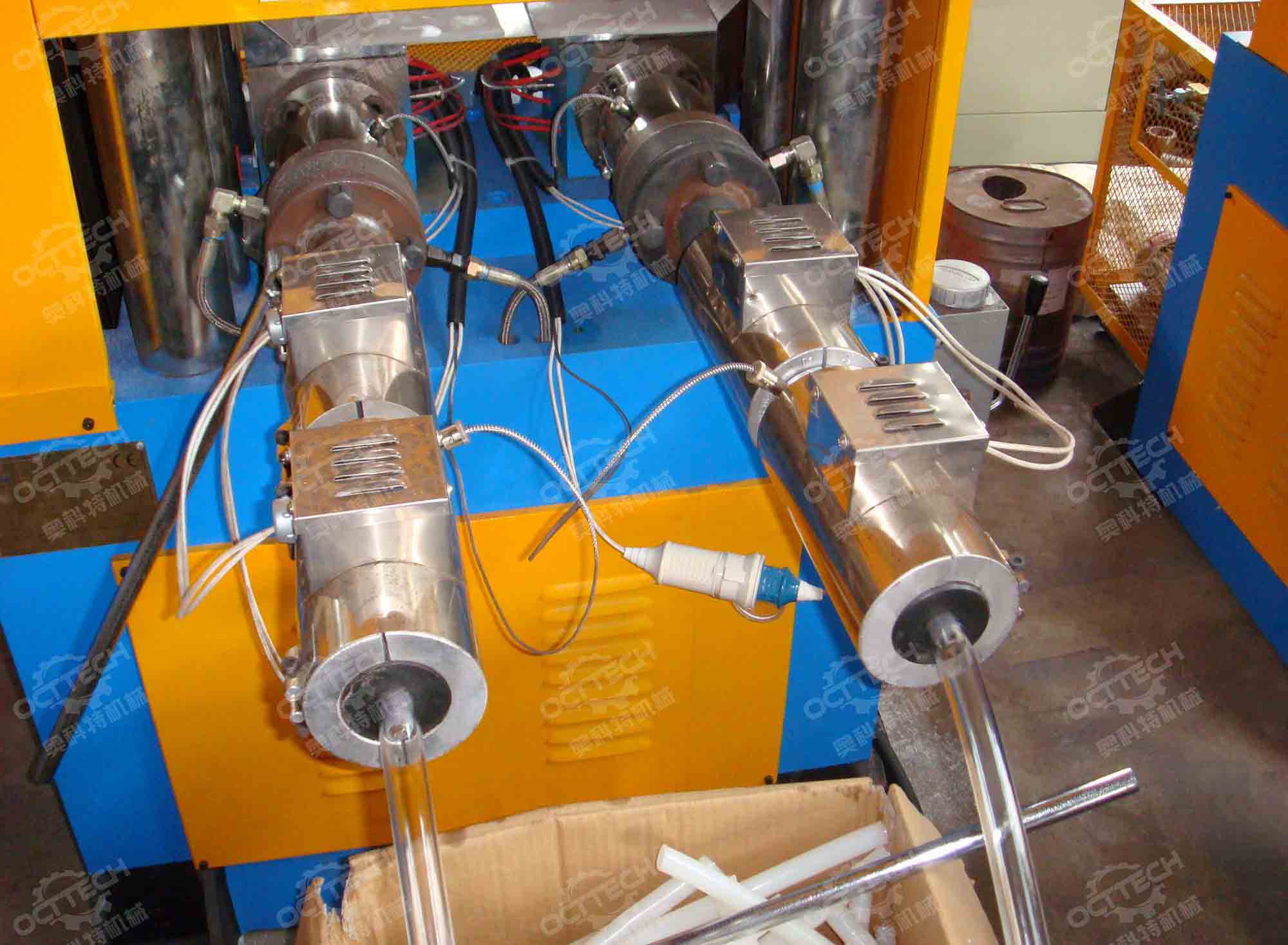

PEX-A pipe machine

This machine uses a plunger extruder to produce PEX plastic pipes. The production process of PEX plastic pipes: PE powder is mixed with peroxide crosslinking agents, antioxidants and other raw materials through a high-speed mixer, extruded by a plunger extruder, crosslinked in the mold, printed, cooled and formed, and then rolled into a disc. This pipe is mainly used for floor heating and heating.

Main technical parameters

Pipe diameter:ф16,ф20,ф25,ф32

Pipe line dimension:11000*1500*2100mm(L*W*H)

Capacity:18-20kg/h

Technical Parameters

| Complete list of PEX-A Pipe Extrusion Machine Line | |

|---|---|

| 1 | PEX-a plunger extrusion machine |

| 2 | Printing device |

| 3 | Cooling tank |

| 4 | Traction device |

| 5 | Winding machine |

| Below are auxiliary machines for PEX-A pipe machine line

(Note:One set auxiliary machines can equipped for six sets pex-a pipe machine line) | |

| 6 | 100L high speed mixer |

| 7 | Oven |

| 8 | Die mouth polish machine |

PEX-A pipe machine Working Flow

Material Vacuum feeding → Hopper dryer → Main extruder → Color extruder →Mould→ Vaccum calibration tank → Spray cooling tank →Meter-measure printer →Haul off machine → Cutting machine(or pipe winder machine)→ Stacker

PEX-A pipe machine Detail

Plunger speed:300times/min

Heating power:6KW

Temperature controller

Contactor:SIMENS

Winder motor power:0.55KW

Motor power:0.75KW

Heating power:10KW

Capacity:100kg/h

Effective volume:75L

Part contact with raw material:Stainless steelr

service advantage

professional installation

Octtech has a professional equipment installation team with professional training and years of service experience. With excellent skills and tools, Octtech can provide fast and reliable lithium battery mixer installation services.

Quick response

The normal operation of the equipment is very important to your work efficiency, so we arrange local professional service technicians all over the country, arrive at the scene within 2 hours, and provide the optimal maintenance solution.

user training

Octtech will rely on its own resource advantages to provide high-quality training services. Let you firmly grasp how to operate the equipment proficiently; understand some basic equipment daily maintenance knowledge.

excellent product

WhatsApp

WhatsApp

Wechat

Wechat