HM foam hot melting machine

HM hot melting machine is used for the big size waste recycling center, the EPS,XPS,EPP,EPE material can all be treated by this unit, and the space of the waste material can be reduced 80%-90%.

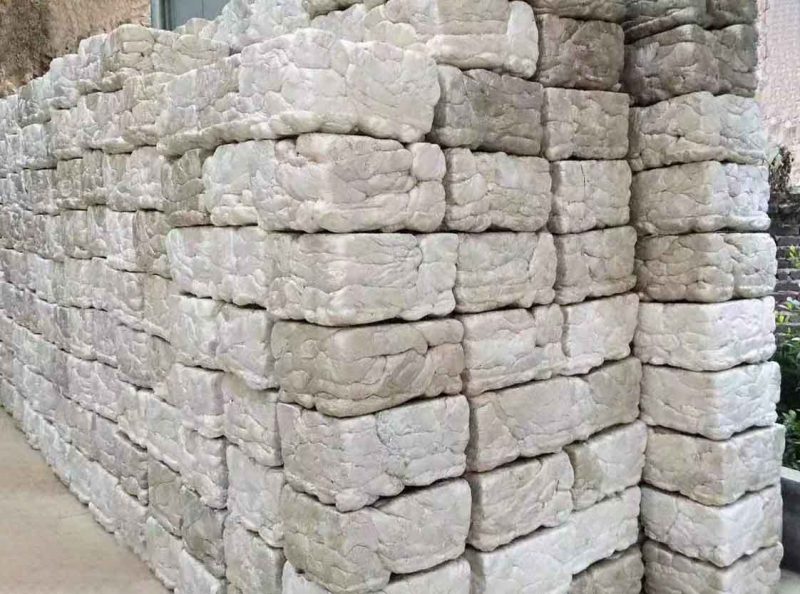

The material you get is the foam material blocks, the user can load it into the container directly to sell it. They can also crush it and make the other products. The density can reach 500-600kg/cubic meter, and one 40 feet container can load more than 20 tons material.

The machine is composed by four parts,

1,Hopper

2,Crusher

3,Extruder

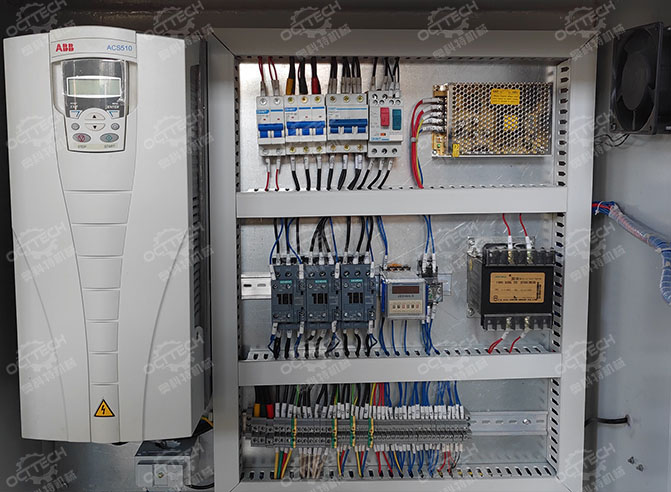

4,Electricity control box

Technical Parameters

| Model | HM-200 | HM-400 |

|---|---|---|

| Screw diameter(mm) | 197 | 200 |

| Screw Length(mm) | 2100 | 2100 |

| Capacity(Kg/h) | 80~120 | 150-200 |

| Extrusion center height(mm) | 326 | 366 |

| Motor power(KW) | 15 | 22 |

| Heating power(KW) | 10kw,3 zones | 14kw,3 zones |

| Crusher motor power(KW) | 3KWx2 | 3KW x4 |

| Crusher blades quantity | 9sets+10sets | 11sets+10sets+11sets+10sets |

| Size L×W×H(mm) | 2800×1580×1950 | 3400×1880×2550 |

| Weight(Kg) | 1400 | 2300 |

HM hot melting machine Detail

Feed the material to hopper by hand or by belt conveyor.

There is a safety switch on the hopper.

Each shafts are driven by two gearbox separately.

There is a screen at the bottom of the crusher tank to filter the material.

There are ceramic heaters on the screw.

In the mold head heating by stick bars which is made by stainless steel.

There are two emergency stop, one is on the panel and the other one is on the machine.

The density can reach 500-600kg/cubic meter.

service advantage

professional installation

Octtech has a professional equipment installation team with professional training and years of service experience. With excellent skills and tools, Octtech can provide fast and reliable lithium battery mixer installation services.

Quick response

The normal operation of the equipment is very important to your work efficiency, so we arrange local professional service technicians all over the country, arrive at the scene within 2 hours, and provide the optimal maintenance solution.

user training

Octtech will rely on its own resource advantages to provide high-quality training services. Let you firmly grasp how to operate the equipment proficiently; understand some basic equipment daily maintenance knowledge.

excellent product

WhatsApp

WhatsApp

Wechat

Wechat