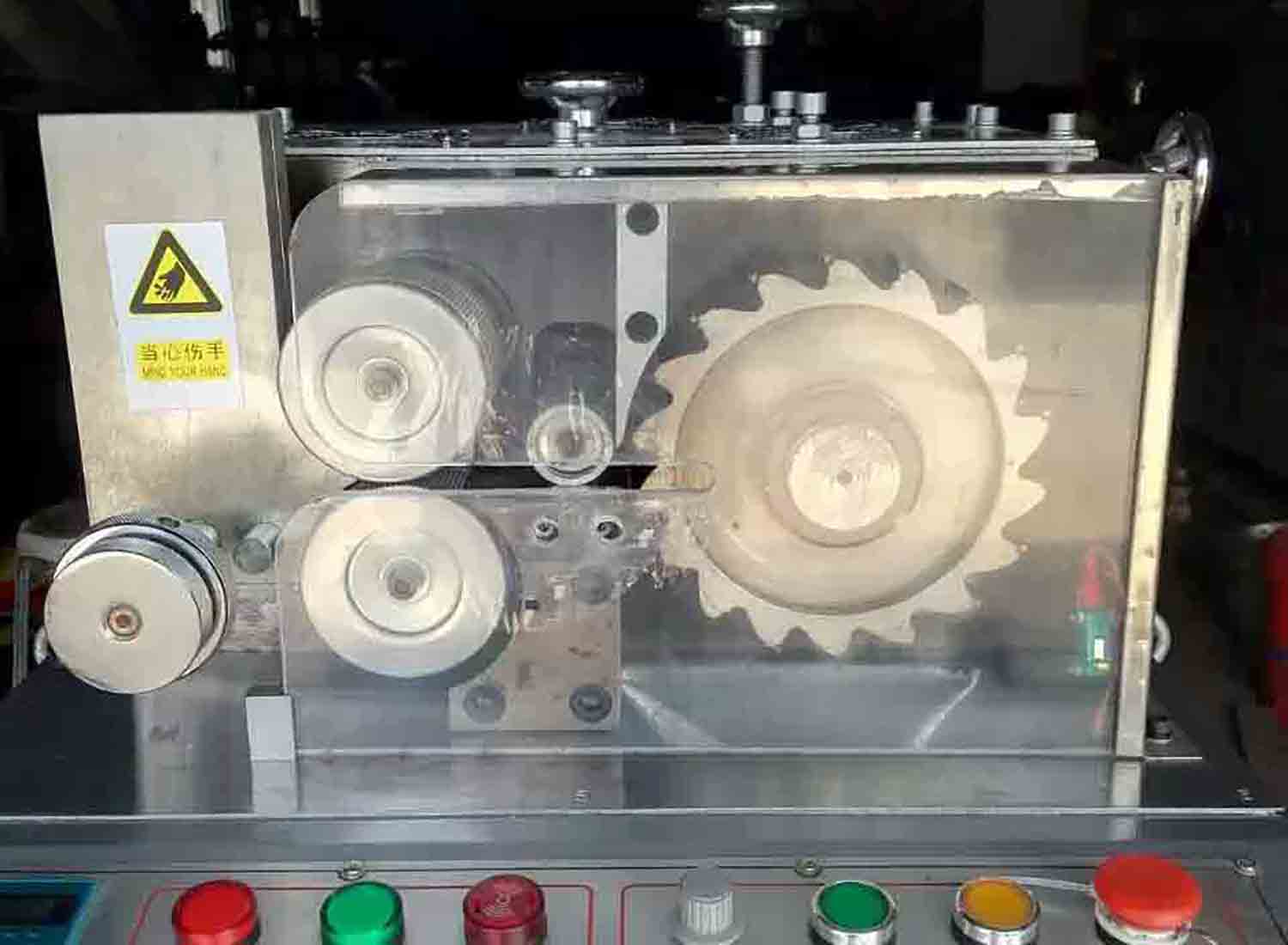

EF180 edge trimming film press pellet machine

Main purpose: Cut and granulate CPE, PE, CPP, PO, PP, EVA, BOPA, POF, LLDPE and other plastic films and non-woven fabric scraps at room temperature, reduce waste storage space, improve raw material utilization, and generate good economic benefits.

Working principle: Feed the edge film into the feeding device, through press device,the irregular edge film will be pressed into regular ribbons type, and then cut into flake granular materials by high-speed rotating alloy blades.

Technical Parameters

| EF180 EDGE FILM PRESS PELLET MACHINE | |

|---|---|

| Final pellet size | 6mm length |

| Recycle mode | Cutting and shaped |

| Product shape | Slice granule |

| Chemistry performance | Identical with original |

| Max. accession amount | 30%-40% |

| Operation method | Separate or online |

| Production speed | ≤90m/min |

| General power | 2-3kw |

| Capacity | 100-150kg/hr |

| Cleanness | No polluted |

| Weight | 220kg |

| Dimension | 85x85x135cm |

More machine photos

service advantage

professional installation

Octtech has a professional equipment installation team with professional training and years of service experience. With excellent skills and tools, Octtech can provide fast and reliable lithium battery mixer installation services.

Quick response

The normal operation of the equipment is very important to your work efficiency, so we arrange local professional service technicians all over the country, arrive at the scene within 2 hours, and provide the optimal maintenance solution.

user training

Octtech will rely on its own resource advantages to provide high-quality training services. Let you firmly grasp how to operate the equipment proficiently; understand some basic equipment daily maintenance knowledge.

excellent product

WhatsApp

WhatsApp

Wechat

Wechat